The advantages of the three-layer wall

Building a house using the three-tier wall technology is a prospective, energy-efficient and, what’s also very important - ecological solution. Find out what other advantages this solution offers.

Thermal insulation

The combination of ceramic hollow bricks with mineral wool or polystyrene panels and facades made of clinker bricks guarantees very low heat transfer coefficient. This solution inhibits the loss of heat, thus reducing the exploitation costs of the building.

Noise protection

Three-layer walls significantly suppress the sound. The greater the mass of the wall, the better the insulation. This type of wall-building technology is important in homes in high-traffic areas, such as busy roads or railroads. By deciding on three-layer walls, we get the best acoustic insulation values, even with very thick supporting walls.

Energy efficiency

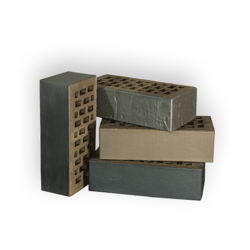

Approximately 70% of energy in residential buildings is used for heating the premises. The best results in terms of thermal insulation are achieved by buildings with outer walls erected using three-layer wall technology. The structure of this type of wall comprises of three layers, providing thermal insulation while also ensuring constant circulation. This is possible due to use of ceramic hollow bricks for construction of a support layer, mineral wool or polystyrene to provide insulation, a ventilation slit and a shielding wall made of bricks. The thermal insulation properties of the three-layer wall can be further enhanced using sanded hollow bricks. A special type of adhesive mortar is used for this purpose, providing a very thin joint, thus minimizing the risk of thermal bridges that are responsible for most of the heat loss.

Utilizing innovative ceramic hollow bricks with mineral wool insert, with heat conduction coefficients (λ) at 0.07, 0.08 and 0.09 W / mK, it is possible to obtain a very favorable heat transfer coefficient (U) of the entire wall. For example, the U-value of a wall constructed as follows: 20 mm (0.25 W / mK) external light plaster - Thermoziegel TV 7-Plan hollow brick with a wall thickness of 365 mm (0.07 W / mK) - internal mortar, gypsum or plaster, 15 mm (0.51 W / mK) is only 0.18 W / m²K. The mineral wool hollow brick can therefore provide an energy-saving wall and reduce heating costs.

Healthy interior microclimate

The use of ceramic hollow bricks guarantees perfect diffusion.

The humid air generated during cooking, bathing or physiological activities, does not settle on the surface of the hollow brick, instead it being vented outside. Thanks to this, the interior of the house has a pleasant atmosphere all year round, favorable to the well-being of its inhabitants.

Durability and endurance

Ceramic hollow bricks are a solid and durable building material. Blocks do not deform as a result of static loads (loadbearing walls) or under the influence of heat or cold. In combination with insulation made of mineral wool or polystyrene boards and clinker brick facades, which protects the inner layers from damage and weathering and optimally contributes to the accumulation of heat in the wall, walls thus produced are robust and durable.

Guaranteed protection against fire

Both ceramic bricks and clinker bricks are non-flammable. With a home built of these materials, there is no need for additional fire protection.

Ecological building

Thanks to the implementation of natural, ecological and biodegradable materials, hollow bricks and standard bricks do not interfere with the environment. Conscious selection of ecological materials promotes better harmony of the house with the environment, and the high-quality raw materials are characterized by very high technical parameters.

Aesthetics

Using face bricks or clinker to build a shielding wall provides an almost unlimited choice of colors and façade designs. The available wide variety of colors, from the most traditional red, through yellow, bronze, white, gray to black finish, with dozens of textures, allows to finish a building in any style. In addition, the brick facade reduces the expenditure on renovations. Compared to other materials used to make outer parts of a wall (in particular plaster), facades made of face or clinker bricks require practically no renovation work. It is recommended for investors for whom the most important thing is the highest quality workmanship, long-lasting durability and aesthetics preserved for years.