Brick chimney – basic principles

The chimney is an indispensable part of the ventilation system, whose effectiveness determines the safety and comfort of the residents. The need to professionally make the chimney results from building standards, which determine, among other things, its basic parameters and location in the entire structure of the building.

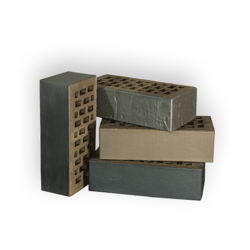

The principles of the building practice also specify the acceptable materials and the way the chimney is made. Even reliable workmanship of a chimney flashing by a roofer will not prevent it from leaking when we decide to use wrong materials or omit the principle of proper joint filling. There is no doubt that ceramic brick is the most frequently used material for building chimneys. It is worth noting, however, that not every type is appropriate in this case. To ensure optimal tightness and protection against leakage, a chimney should be made of solid bricks along its whole length, also in the part protruding above the roof surface.

Bricklayers often make a mistake and use full bricks only at the bottom layers, or make the entire chimney from hollow bricks.

Such solutions may allow the rainwater to get under the roofing, causing moisture and reducing the thermal insulation properties.

Another rule that should be observed when constructing a chimney is the proper joint filling. First of all, the joints should be full and tightly fill the space between the bricks. It is not advisable to build using empty or sunken joints, because the water accumulates in unfilled spots, weakening the durability of the chimney structure. It is also important to arrange the bricks properly. Their individual layers should form a so-called stretcher bond, in which the vertical joints are staggered in relation to each other by half a brick length. To sum up, the use of full brick, tight filling of the joint and the stretcher bond are the basic principles of chimney construction, enabling to effectively avoid the problem of leakage.